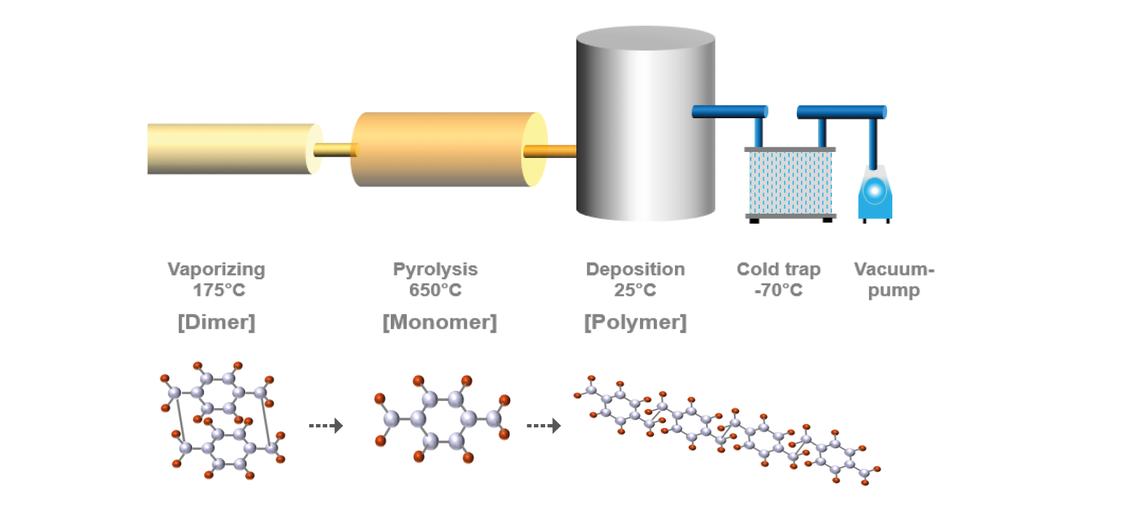

Protective coating with Parylene is a three step manufacturing process where Parylene in its monomer form is deposited on the substrate in a vacuum chamber to build a polymeric conformal coating.

Protective coating with Parylene is a three step manufacturing process where Parylene in its monomer form is deposited on the substrate in a vacuum chamber to build a polymeric conformal coating.

The first step is the vaporization of firm dimer. The dimer is heated to a temperature of 175°C and is dissipated in a gas.

The gas is then pyrolysed (thermo chemical cleavage of organic compounds) to transform the dimer in its monomeric form.

The monomeric gas is deposited in the deposition chamber under room temperature as a transparent polymeric film. The obtained coating layer thickness can vary with the application and can amount from 1 µm up to 50 µm.

Paratech Coating Scandinavia

Elektronikhöjden 6

17543 Järfälla

Tel. +46 (0) 8 588 823 00

Sweden

Account Manager

Phone: +46 (0) 8 588 823 03

Mobile: +46 70 108 00 49