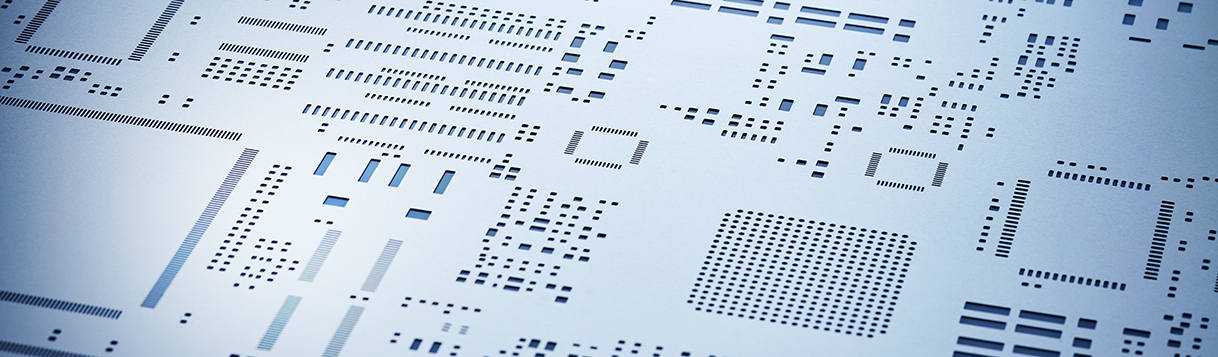

HP Etch is able to make apertures for components with pitch down to 0.25 mm.

We manufacture in standard thicknesses:

0.08, 0.10, 0.11, 0.12, 0.13, 0.15, 0.18, 0.20 and 0,25mm, beyond that we can step down to thinner thickness.

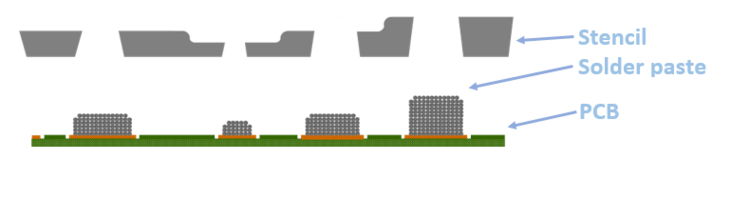

We can step etch to different thicknesses on the same stencil even on both sides. have support with great technical knowledge and long experience in the industry.