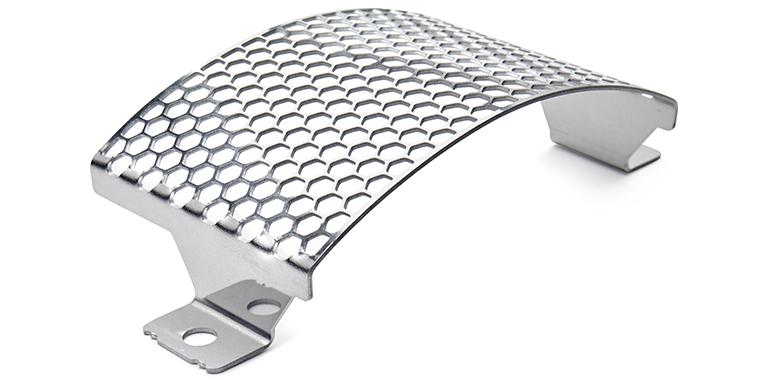

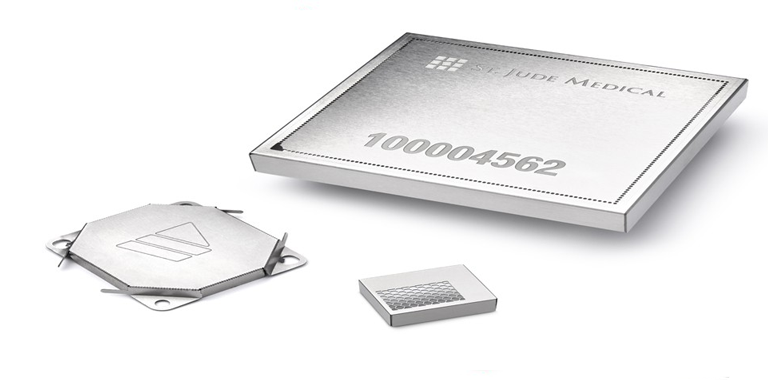

For satellites or airplanes, HP Etch can produce high strength metal etched parts that can withstand extreme temperature fluctuations and high mechanical loads.

In the aerospace industry metals are used, which are very wear-resistant, corrosion-resistant, but very light. Aluminum and Titanium are often used, which are difficult to process with conventional metalworking processes and cause high costs. By the etching process, the known advantages, such as freedom from burrs, no forming residues and no thermal effect can be used.

Also clad materials, e.g. Aluminum-Steel or Copper-Titanium are used in aerospace applications and, as etched versions, offer various advantages.

Highest Requirements for Etching Moldings

Contact us for more information

Sheet Technology

HP Etch AB

Elektronikhöjden 6

17543 Järfälla

Tel. +46 (0) 8 588 823 00

Sweden

Reel-to-Reel Technology

micrometal GmbH

Renkenrunsstraße 24

79379 Müllheim (Baden)

+49 (0) 7631 93688-0

Germany