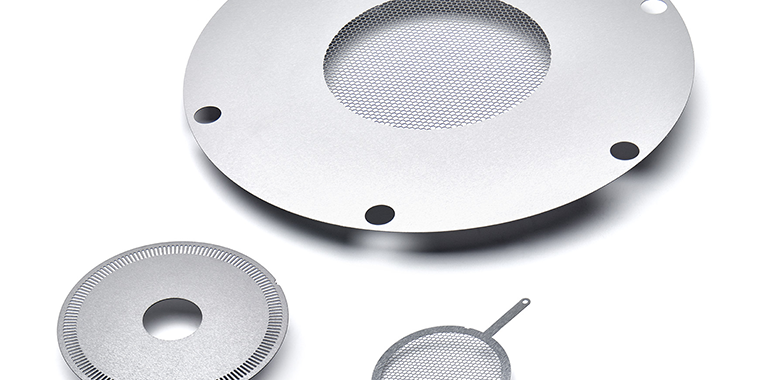

HP Etch manufactures many different etch parts for the automotive industry, i.e. fuel injection, filters, decorative elements, precision springs, electrical contact parts, wiring components, etc.

Etching vs. punching

The etching process offers advantages in comparison to the traditional stamping process, which is mainly used when the application is exposed to heavy loads. The punching process can cause hairline cracks and causing breaks. Etching can be done without any structural change and mechanical stress. Since low tooling costs incurred, the desired precision etched parts are economically attractive and quickly available.

Prototypes

A very special positive aspect is the prototype production. With a quantity of one piece and above, you can specifically test your prototype requirements. If it then comes to series production, we can offer you - in addition to our sheet technology - through our parent company, micrometal GmbH, the etching process in a continuous process (reel-to-reel).

Precision Etched Parts for the Automotive Industry

Contact us for more information

Sheet Technology

HP Etch AB

Elektronikhöjden 6

17543 Järfälla

Tel. +46 (0) 8 588 823 00

Sweden

Reel-to-Reel Technology

micrometal GmbH

Renkenrunsstraße 24

79379 Müllheim (Baden)

+49 (0) 7631 93688-0

Germany